The belt grinding machine for a wide range of application- Optimized sample preparation for perfect analysis and cost-efficiency of your laboratory

Use

Coarse grinding of of steel and pig iron samples for OES, XRF and other analytical procedures

Material

Steel and pig iron samples, diameter up to 50 mmm, round or with parallel surfaces

Operation mode

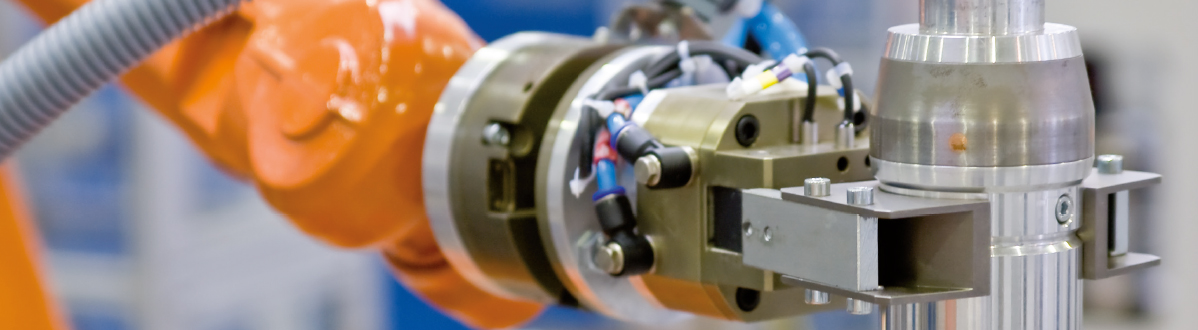

Automatic, standalone, linear automation, robot automation

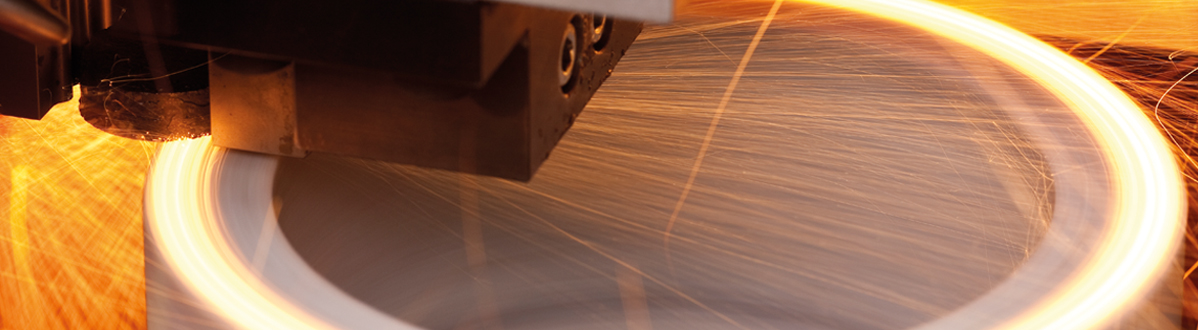

Precision at high speed

The HB 4000 is characterized by quick and precise grinding of iron and steel samples with widely differing compositions, geometries, hardnesses and temperatures up to 800 °C. A pneumatic clamping unit allows symmetrical samples with diameters of up to 60 mm to be gripped reliably and in a defined position, thus enabling high grinding capacities and short sample preparation times.

Combination of different grinding techniques

Roughing on the coarse belt grinding offers long service life. The fine grinding of extremely hard samples on the 200 mm wide grinding results in higher quality, longer service life, and lower abrasive costs. The width of the grinding belt enables different samples to be fine ground on several tracks – this reduces cutting material costs and time due to reduced grinding belt consumption and replacement. Preselectable grinding belt zones prevent cross-contamination of the samples during the preparation of different sample qualities.

The HB 4000 with its integration of the different machining methods, "Coarse Grinding " and "Fine Grinding" ensures optimum sample preparation for the analytical requirements for samples with all degrees of hardness and alloys.

On steel with very low carbon contents, abrasives can leave residues in the form of minute carbon particles which lead to falsified and useless analysis results. For these samples the "Automatic Grinder and Miller HBF 4000" is available.